Services

Welding Services in Midwest

Ready to get started?

Welding Services in Midwest

Producing Consistency and Quality

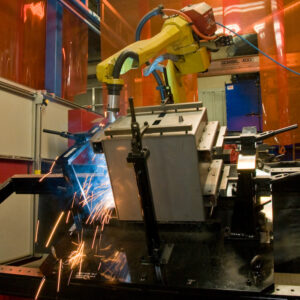

Clean, consistent welds are where it all comes together in the fabrication process. We employ highly-skilled welders and leverage robotics to ensure materials are joined properly to meet tight tolerances and standards. We continuously train in-house to achieve the highest levels of AWS standards and certifications to produce quality results using innovative techniques.

With the most advanced robotic welding technology available—MIG, TIG, PRI Lincoln and Genesis Versa 2L and more—we deliver consistency and precision in even the most challenging situations. With decades of experience and commitment to creating solutions that last, thin metal, hard-to-reach areas and other welding issues are easy to manage and overcome. This level of detail also supports seamless assembly and finishing.

ROBOTIC WELDING EQUIPMENT

NEW Acieta Large Weld Cell (“BigBot”)

74″ swing

Bed length 159″

8487# capacity

PRI Lincoln System 55 Robotic Welder

60″ swing, 108″ bed length

1600# capacity

Genesis Versa 2L Robotic Welder

60″ swing, 144″ bed length

5000# capacity

Trumpf TruArc Weld 1000

Working range of 23.6″ x 23.6″ x 23.6″ with center divider down and 78.74″ x 23.6″ x 23.6″ with the center divider up

WELDING EQUIPMENT

State-of-the-art Lincoln MIG and TIG Welders

Modular Fixture Tables

WELDING CERTIFICATIONS

- ASME Section IX

- NAVSEA S9074-AQ-GIB-010/248

- MIL-STD 248D

- MIL-STD 1595A

- AWS B2.1

- AWS D1.1

- AWS D1.6

- AWS D9.1

- AWS D17.1

- AWS Robotic Welding Certification Standards

(other standards on request)

A JONES METAL INSIGHT

Collaborating to Create the Ultimate Welding Workforce